Suponsered by

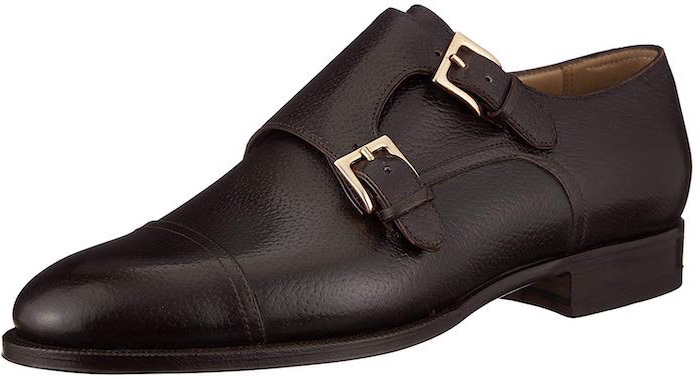

7 steps to make Enzo Bonafe’s leather shoes

(1) Planning and cutting

Enzo Bonafe’s leather shoe making process starts with carefully imagining the finished product from the planning stage. He designs models based on the valuable feedback he receives from his bespoke clients and end users. The finest leather is selected, and the vamp (the toe part), which greatly affects the quality of the shoe, is cut by hand.

(2) Stitching the upper

From the cutting of the vamp to the stitching of the upper, the entire process, from start to finish, is always done by a single craftsman. The quality of the product is guaranteed by having one craftsman concentrate on a single pair of shoes instead of dividing the workload.

(3) Assembly

Shoe assembly is also done by hand. Pliers, hammers, and nails are used to form the shoes in the traditional way. Enzo Bonafe believes that “machines are convenient and can help the craftsman to a certain extent, but they can never be a substitute for the taste and expertise of a craftsman with decades of experience.”

(4) Shaping the shoe

After shaping the leather shoes, they are further shaped by beating them into shape. This process, which is very specific, is probably not necessary for modern footwear. However, this step is essential for Enzo Bonafe’s leather shoes, as it gives them the right “edge” and ensures a perfect fit. Of course, no machines are used in this process, and the only tool used is a hammer.

(5) Sewing the sole

The sole stitching is the highlight of the craftsman’s skill. In addition to the various techniques used to attach the soles, Enzo Bonafet also performs a lot of work before and after the stitching process to ensure reliability and comfort.

(6) Cleaning the sole and coloring the heel

Sole cleaning and heel coloring are also tasks that only a craftsman with specialized skills can perform. In addition to making the shoes beautiful, the discerning technicians thoroughly eliminate any problems or minor imperfections that the leather material may have.

(7) Polishing

The final step is to polish all shoes using only the best creams. The use of unnecessary sprays and polishes is strictly forbidden for leather that is naturally fine and beautiful. By using the minimum amount of cream and polishing slowly, the shoes will naturally carry light. No matter how long this process takes, it is done until the shoes take on a clean light that is befitting of Enzo Bonafetto’s leather shoes.

Click here for details and purchase

3/6GO TO NEXT PAGE

![A roundup of the 65 most popular brands of jeans [ 2024 Denim Latest ].](https://otokomaeken.com/wp-content/uploads/2015/04/777f096a10d40de2a7037fce7da8f708-115x60.jpg)