Suponsered by

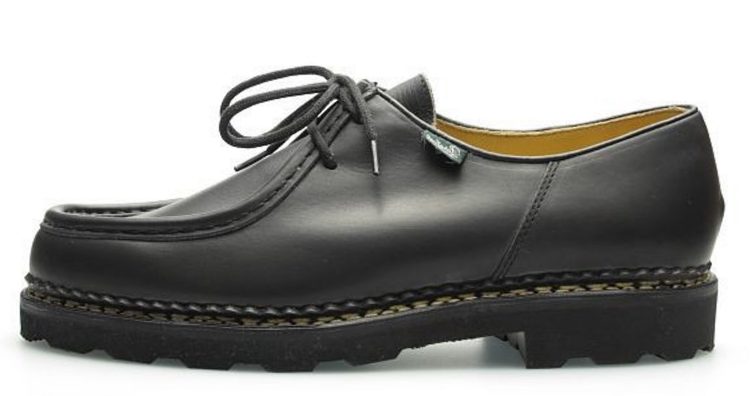

This is Paraboot’s signature! The Norwegian manufacturing method that gives the ” Michael ” its weight and durability.

Of the more than 150 processes involved, the soling process is the most time-consuming and technical. Mikael is tailored using the Norwegian method. As the name suggests, this method originated in Norway, and until about half a century ago, it was known as a typical manufacturing method used for outdoor shoes such as mountaineering boots and ski boots. Paraboot’s Norwegian manufacturing method, which was originally used for mountaineering shoes, is one of the highest in the world.

It is similar to the Goodyear welt method often seen in dress shoes in that it sews through the welt and thickly packs cork as a cushioning material between the midsole and outsole. The difference is that the welt is not inside but outside, and the L-shaped folded welt is buried exactly at the border between the upper and sole, making it visible from the outside. Unlike the Goodyear welt method, where water can enter through the border between the welt and the upper, in the Norwegian method, the welt serves to prevent water from entering.

The design is also distinctive, with both the “scoop stitch” stitching that sews the welt to the upper and the “dashii” stitching that sews the welt to the sole visible. The thread is thick and the welt itself is sturdy, creating a casual impression. The functionality is also outstanding, with excellent waterproofing that allows the wearer to wear them in any weather, as well as excellent cushioning that conforms to the foot as the wearer wears them in. The manufacturing process is based on mountaineering shoes, and this method allows for a stable gait even on rocky terrain with protrusions. The Norwegian manufacturing process alone takes two days to make one pair of Mikael, and more than 800 seams are sewn by craftsmen.

Storm welt with a mountain-shaped design that adds a decorative touch.

The design of the L-shaped welt touching the upper is also known as a ” storm welt. This specification, which means “storm” in Japanese, literally protects the shoe from rain, wind, and dust. It also has the effect of preventing the leather upper from being scratched, and many shoes adopt it as a counterpart to make the shoe look voluminous. In Mikael, the storm welt is further enhanced with a mountain-shaped, jagged design.

6/6GO TO NEXT PAGE

![Leather shoes Recommendation ranking [ TOP 35 ].](https://otokomaeken.com/wp-content/uploads/2018/01/38a08a1c70f3cbbc6ffc1c8025f11d35-630x331.jpg)

![Shoe keepers [ 5 things to keep in mind when buying ].](https://otokomaeken.com/wp-content/uploads/2017/11/54c39ddccbab69e5776cb0bee1780583-630x331.jpg)