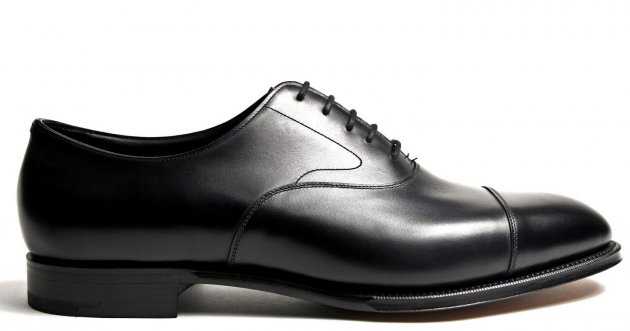

Jalan Sriwijiya, from Indonesia, is the most cost-effective leather shoe brand, offering high-end-level performance for around 30,000 yen. In this issue, we will thoroughly dissect the appeal of the “98490” U-tip shoes produced by Jalan Sriwijaya, a brand that is now as well known and competent as British and Italian shoes.

Suponsered by

History of JALAN SRIWIJAYA

The roots of Jalan Sriwaya, a factory brand (original brand of a production factory), go back nearly 100 years. 1919, Mr. Tedde Chandra founded Jalan Sriwaya’s factory, “Fortuna Shoes,” in Indonesia. At the time, Indonesia was a Dutch colony. Therefore, the shoe factory that was the predecessor of Fortuna Shoes also manufactured military boots for Dutch soldiers. Later, when the Republic of Indonesia became independent, the factory started anew in the 1970s as ” Fortuna Shoes Sdn. Leather sandals became a big hit in Indonesia, and the company further focused on casual shoes such as deck shoes and driving shoes, and started exporting them outside the country.

The president of the company, Mr. Tedde Chandra, and his son, Mr. Rudy Sparman, who manages production, went to Europe to study footwear with the thought that ” the time for peace is coming. He learned about leather production at a tannery (leather factory) in France, a country that has been a producer of high-quality leather since that time, and he learned the hand-sawn welted method of shoemaking in Northampton, England, a sacred place for leather shoemaking. Rudy Sparman’s efforts to make the connections necessary for shoemaking while training in France and England have resulted in Jalan Sliuaya’s high-quality materials and quality that rival that of the British shoe industry.

[ Related article ] Introducing the charm and standard models of “JALAN SRIWIJAYA,” a leather shoe brand with the strongest cost performance!

JALAN SRIWAYA’s Commitment to Materials

France is one of the world’s leading leather countries where “Dupuis”, known as a tannery under the umbrella of Hermes, and “Alinois”, a goodwill company of Dupuis, are competing with each other. J.M. Weston, Church’s, and other famous European shoe makers use French leather. As mentioned above, Tedé Chandra and Rudy Sparman, who studied leather in France and built up contacts at many tanneries, continue to make shoes today using the same high quality French leather as that used in high-end shoes.

Jalan Sriwaya’s leather shoes are made using the hand-sawn welding method, yet are extremely cost-effective!

Jalan Sliuaya’s greatness lies not only in its materials but also in its manufacturing methods. While the price range of Jalan Sliuaya’s products is around 20,000 to 30,000 yen, most of the soles are made by hand using the ” hand-sawn welding method. Most of the high-end shoes made in Europe use the ” Goodyear-welted method,” and the hand-sawn-welted method is the prototype of the Goodyear-welted method. This method does not use ribs, which reduces the amount of cork used in the space between the inner sole and the main sole, and the sole returns better than with the Goodyear-welted method. However, due to the large number of man-hours involved, the cost of this method would be well over 100,000 yen for other shoe brands. This alone should tell you how superior Jalan Sliuaya’s shoes are.

What is the secret behind the overwhelming cost performance?

The most significant characteristic of Jalan Sriwaya shoes is that they are ” inexpensive. One of the main reasons for this is the low cost of labor in Indonesia. The average monthly income of Indonesians is about 20,000 yen. In addition, by reducing the number of labor hours on the production line, the company is able to handle lots of several hundred pairs per day and reduce production costs without lowering the quality of the materials.

View this post on Instagram

For example, Jalan Sliuaya’s “nine-part tailoring” hand-sawn welted manufacturing method, in which only the first stitching is done by machine and the rest of the sole attachment is done by hand by craftsmen, is a key selling point. This allows us to reduce the number of processes and to reduce the number of stitches. This not only reduces the number of processes, but also simplifies the soling process, which is said to take 10 years to master, making it possible for young craftsmen to work on it. In addition, by reducing and simplifying the number of steps to the extent that they do not affect the invisible parts, comfort, and feel of the shoes, such as roughing up the ” cork ” used to fill the gap between the inner sole and the outsole, the company has been able to keep the price low, which is not the case with other imported shoes.

2/2GO TO NEXT PAGE

![Rain Protection for Leather Shoes [ 6 Things to Do to Wear Your Favorite Shoes in the Rain ].](https://otokomaeken.com/wp-content/uploads/2021/05/3d94c0146156fcb1049939849487c91d-630x331.jpg)

![Waterproof spray for shoes [ how to choose without fail & 18 recommendations ].](https://otokomaeken.com/wp-content/uploads/2024/03/82ca73c489d79da5328aaacae7d2266d-630x331.jpg)