Suponsered by

Three charms that Bean Boots boasts

Attraction of Bean Boots (1) “Full-grain leather upper that combines robustness and design

Bean boots are still made in the same way as the first boots made by the company’s founder, Leon Leonwood Bean, in 1912. One of the most representative features is the leather upper. By using high-quality full-grain leather that repels rain and snow, the company succeeded in providing waterproof performance, which was revolutionary at the time. In addition, by integrating the shoe’s tongue, rain and snow are kept out. The leather around the ankle, rather than being made entirely of rubber, is also an original design feature.

Appeal of Bean Boots (2) “Rubber bottom for unparalleled waterproofing and grip

There are many boots with rubber outsoles, but the Bean Boots are made of rubber, even the bottom part that covers the instep. This makes them more waterproof than ordinary boots, and the sealed construction prevents water from seeping in. Incidentally, bean boots are designed to be worn with thick socks and are slightly larger than usual.

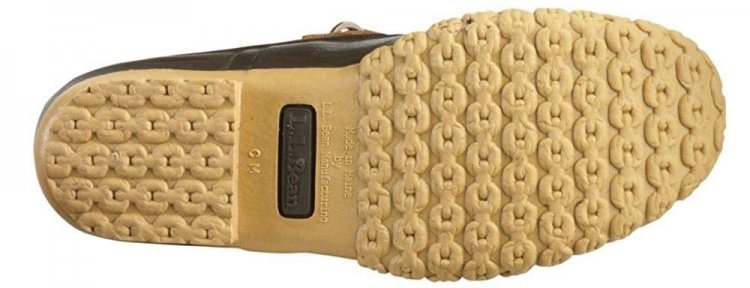

The outsole of the bean boot is called a ” chain sole. As the name suggests, it has a unique tread pattern that grips the ground firmly even on snowy roads. Originally, the boots were designed for wetlands in Maine, the state where the Bean Boots were born, and they are characterized by their ability to easily absorb slush and water.

The bottom part of the Bean Boots can be “resole”!

Bean boots can be re-soled by leaving the leather upper intact and replacing the rubber bottom with a new one. The border between the leather and rubber is cut with a thread saw to leave only the leather, and the bottom is stitched with new thread to match the original stitching at L.L. Bean’s main factory in the U.S. The boots are then re-soled. Boots requested from Japan are sent out for repair in batches to reduce the cost of resoling, so it takes about three months for the boots to be returned. The cost varies depending on the model, but a typical pair of Bean boots starts at 9,500 yen. As long as you take good care of the leather parts, you can enjoy them for many years.

Attraction of Bean Boots (3) “Triple Stitching, a Trademark and Proof of Durability

Bean boots are not only waterproof but also durable, and this is due to the high level of craftsmanship; it takes about 500 steps to make one pair of boots. A particularly noteworthy detail is the triple stitching that connects the upper to the bottom. This trademark triple stitching can only be done by a craftsman who has been trained by Elle Bean for 26 weeks. The finger loops, which tend to take a lot of load, are sewn firmly with inverted V-shaped stitches, which is also a distinctive feature.

3/4GO TO NEXT PAGE