Suponsered by

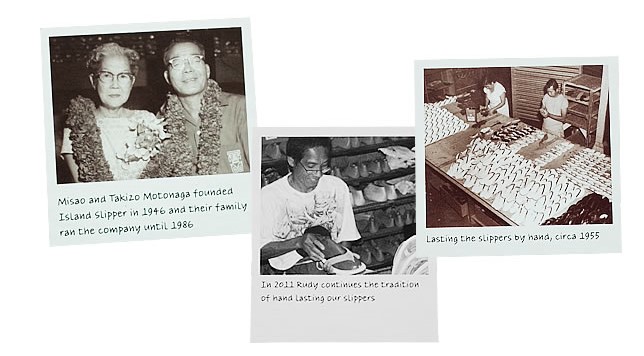

Handmade in Hawaii, family style”, kept alive in the place where the company was founded

In 2006, Island Slipper opened a directly managed store, but the president, Mr. Carpenter, still values the Motonaga family. It is ” a family business. Even after successfully expanding overseas, Island Slipper still handles everything from design to manufacturing at its own factory in Pearl City on the island of Oahu. His “family,” as he calls them, consists of nearly 40 craftsmen who continue to hand-make each pair of sandals every day. The production process is as follows.

STEP1: Cutting of the base sole

The foot pattern of the original pattern, which has six types in total, three each for men and women, is placed on a large sheet of rubber, and each piece is cut by hand.

STEP2: Overlapping the sole to give the sandal cushioning

The three cut soles (outsole, midsole, and insole) are overlapped and glued together. The soft and comfortable cushioning of the island slippers is created in this process.

STEP3: Cover the insole with each textile

Once the thick insole is finished, cover it with a textile of the material and color of each item, such as leather or fabric, and sew carefully along the pattern.

STEP4: Print the Island Slipper logo

Print the ” Island Slipper ” logo on the insole. logo is printed on the insole. Using the same principle as iron printing, place the sole in the default position and engrave the brand name, being careful not to tilt or shift the sole.

STEP5: Punch holes for the straps

Punch holes in the sole for the straps. The strap, which is the key to the design of the island slipper, is prepared in advance by cutting or wrapping cloth around it. This is the process by which the fashionable appearance of the reputation can almost be seen.

STEP6: Apply a wooden pattern to improve fit

Various types of wooden patterns are applied to the part covering the instep of the foot, and the fit when worn is fine-tuned to produce the desired result. This improves the fit of the foot and reduces fatigue when walking with a stable fit.

STEP7: Finishing

Finally, completion! After the insoles and soles of the sandals are glued together, they are put through a press machine, and finally the finished sandals are checked one by one.

You can watch some of these scenes from the following video made to commemorate the 70th anniversary of the company, so check out the “family” love that has been spun through careful handcrafting.

4/10GO TO NEXT PAGE

![A roundup of the 65 most popular brands of jeans [ 2024 Denim Latest ].](https://otokomaeken.com/wp-content/uploads/2015/04/777f096a10d40de2a7037fce7da8f708-115x60.jpg)